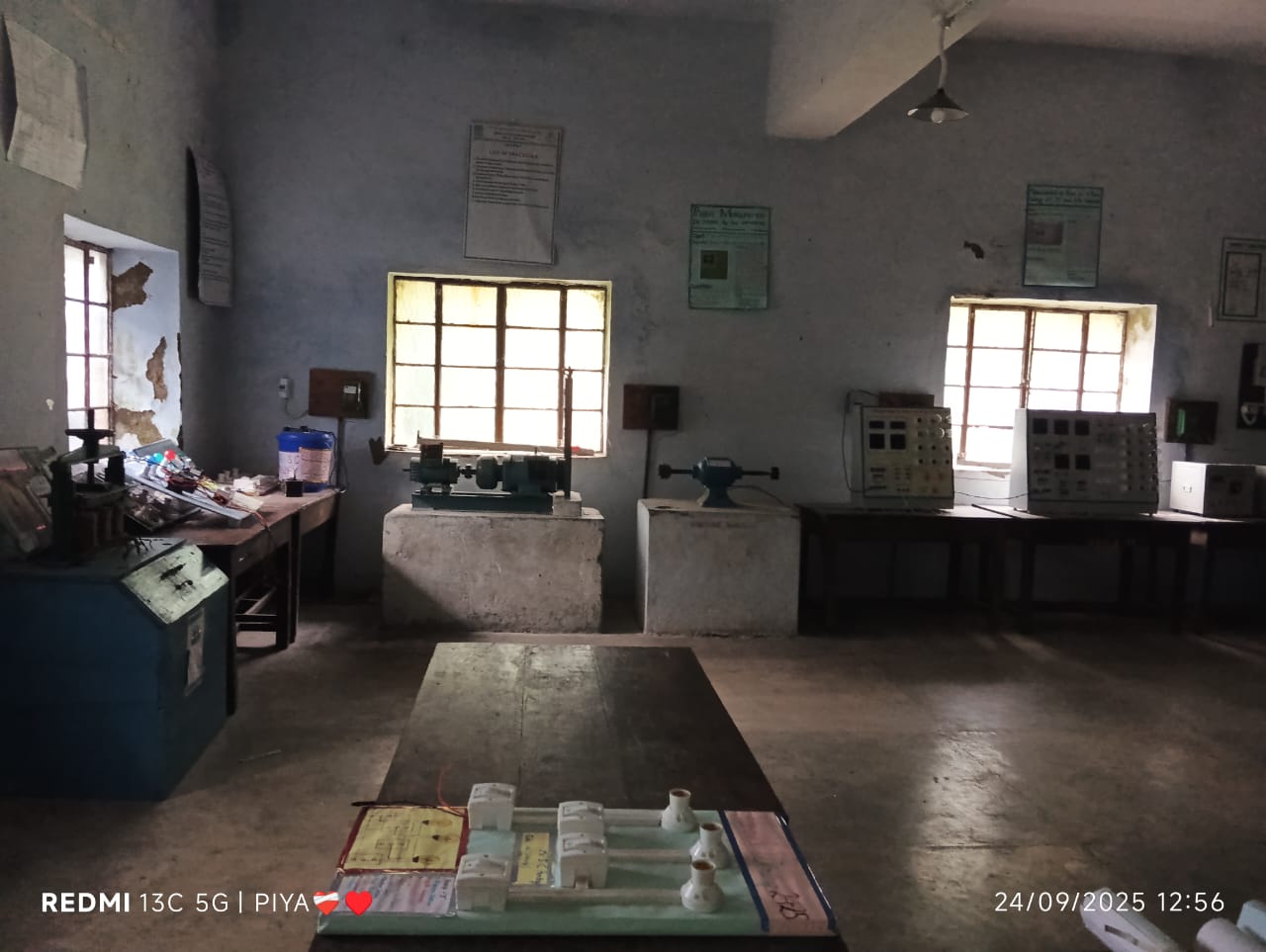

Workshop Practice

First Year Engineering - Hands-on skill development for all engineering disciplines

Explore Workshop ShopsWorkshop Practice Overview

Course Objectives

Filter Workshops

Workshop Shops

Loading workshops...

First Semester Workshops

Fitting Shop

Learn metalworking skills including marking, sawing, filing, drilling and tapping operations.

- Duration: 40 periods

- Tools: Files, hammers, vices, drills

- Workshop Block A

Carpentry Shop

Develop woodworking skills including sawing, planning, chiseling and various joint making.

- Duration: 40 periods

- Tools: Saws, chisels, planes, hammers

- Workshop Block B

Electrical Shop

Learn basic electrical wiring, safety measures, and working with common electrical appliances.

- Duration: 28 periods

- Tools: Multimeter, pliers, screwdrivers

- Electrical Lab

Second Semester Workshops

Sheet Metal Shop

Learn to work with metal sheets including cutting, bending, and joining operations.

- Duration: 30 periods

- Tools: Snips, punches, mallets

- Workshop Block C

Welding Shop

Learn various welding techniques including arc welding and gas welding with safety precautions.

- Duration: 30 periods

- Tools: Welding machines, electrodes

- Workshop Block D

Smithy Shop

Learn traditional forging techniques including heating, hammering, and shaping metal.

- Duration: 25 periods

- Tools: Anvils, hammers, tongs

- Workshop Block E

Electronic Shop

Learn electronic component identification, soldering techniques, and circuit assembly.

- Duration: 20 periods

- Tools: Soldering iron, multimeter, pliers

- Electronics Lab

Plastic Moulding

Learn about plastic materials and production techniques using bench moulding machines.

- Duration: 15 periods

- Tools: Bench moulding machine

- Workshop Block F

Why Workshop Practice is Important

Hands-on Experience

Gain practical skills that complement theoretical knowledge and prepare you for real-world engineering challenges.

Safety Awareness

Learn essential safety protocols and develop a safety-first mindset crucial for any engineering environment.

Problem Solving

Develop critical thinking and problem-solving abilities by working through practical engineering challenges.